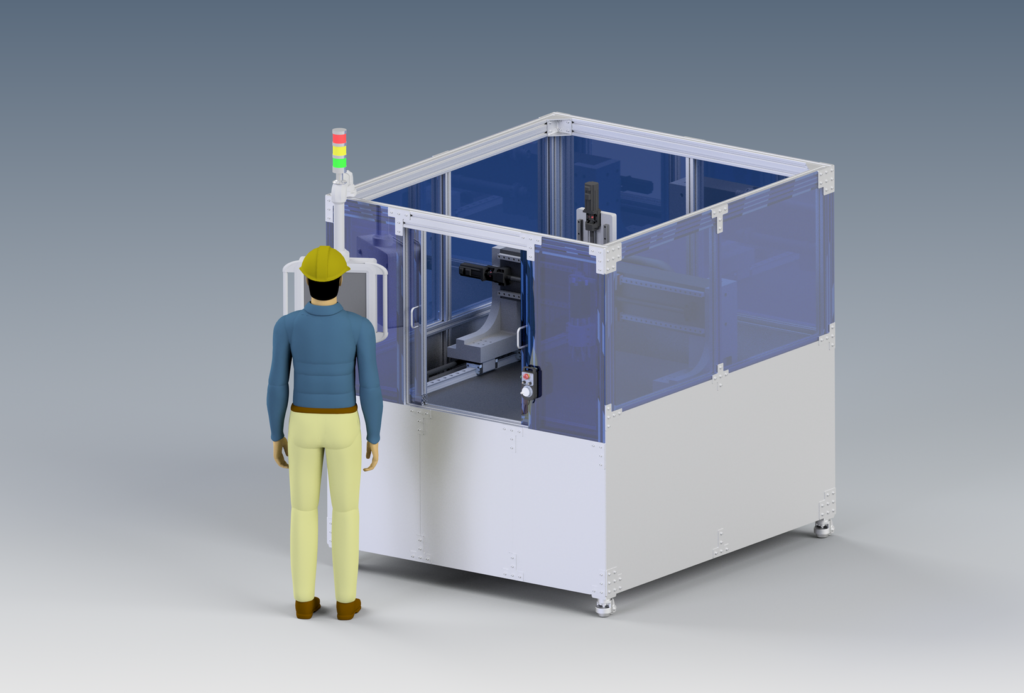

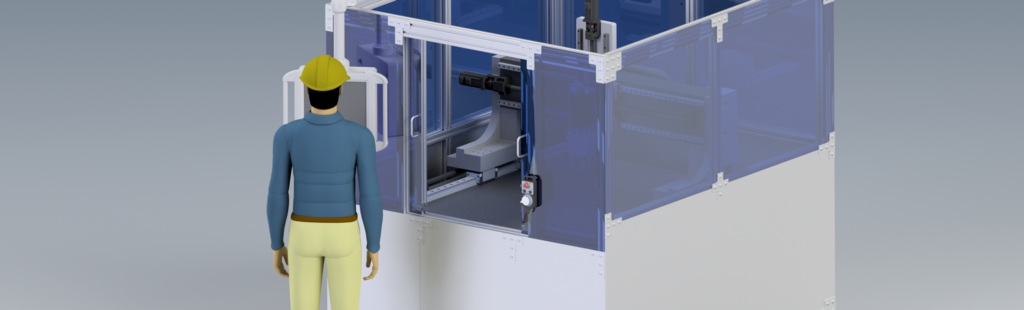

The High-precision CNC Router for manufacturing aluminum parts is a prime example of advanced engineering, designed and developed to ensure exceptional accuracy and reliability in the manufacturing of high-quality aluminum parts. The machine is a cutting-edge technology product that has been designed with precision, combining the latest engineering techniques and technology components.

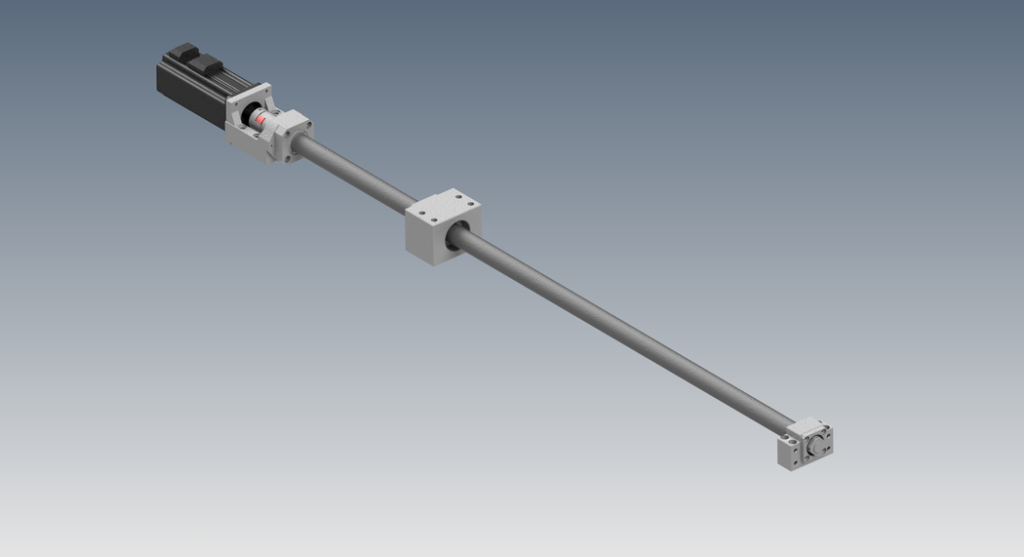

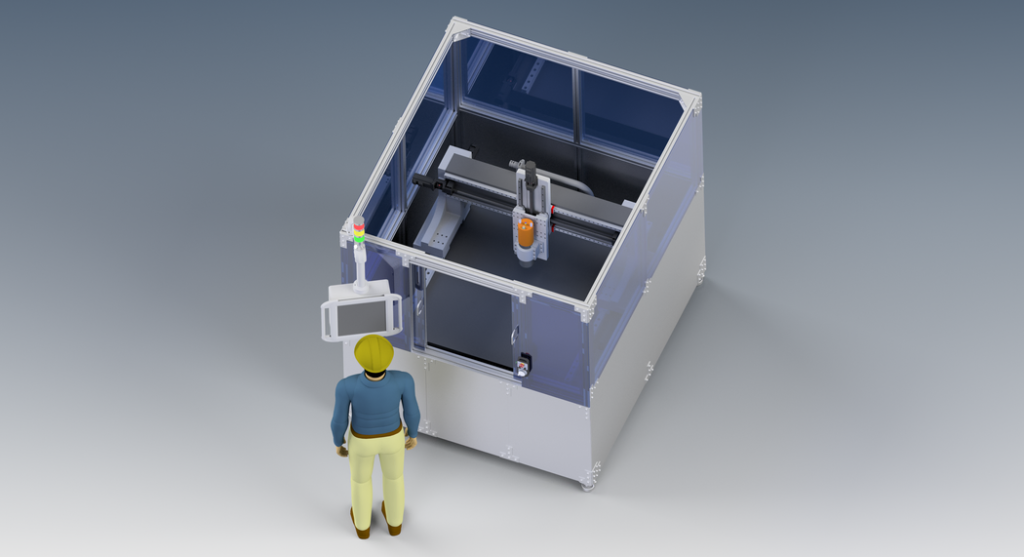

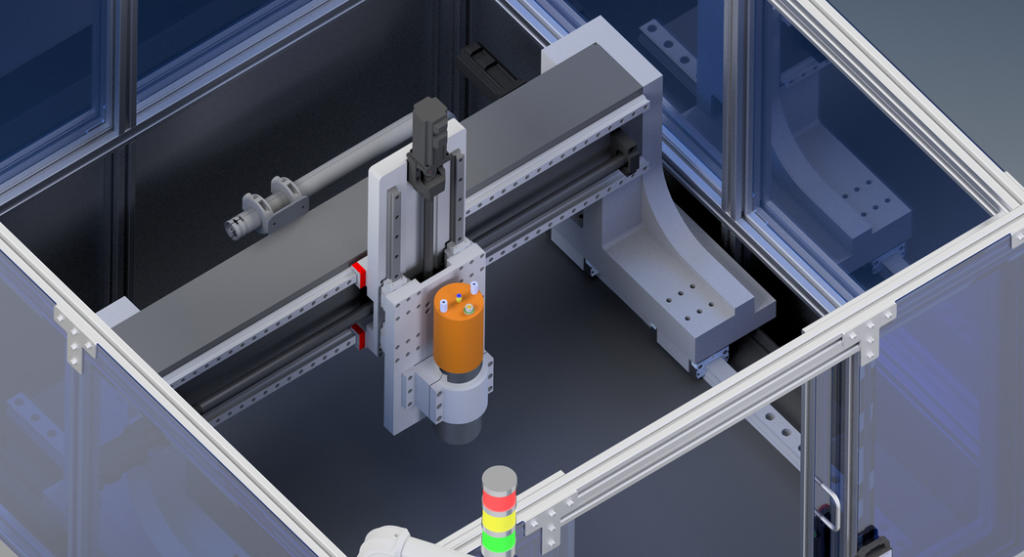

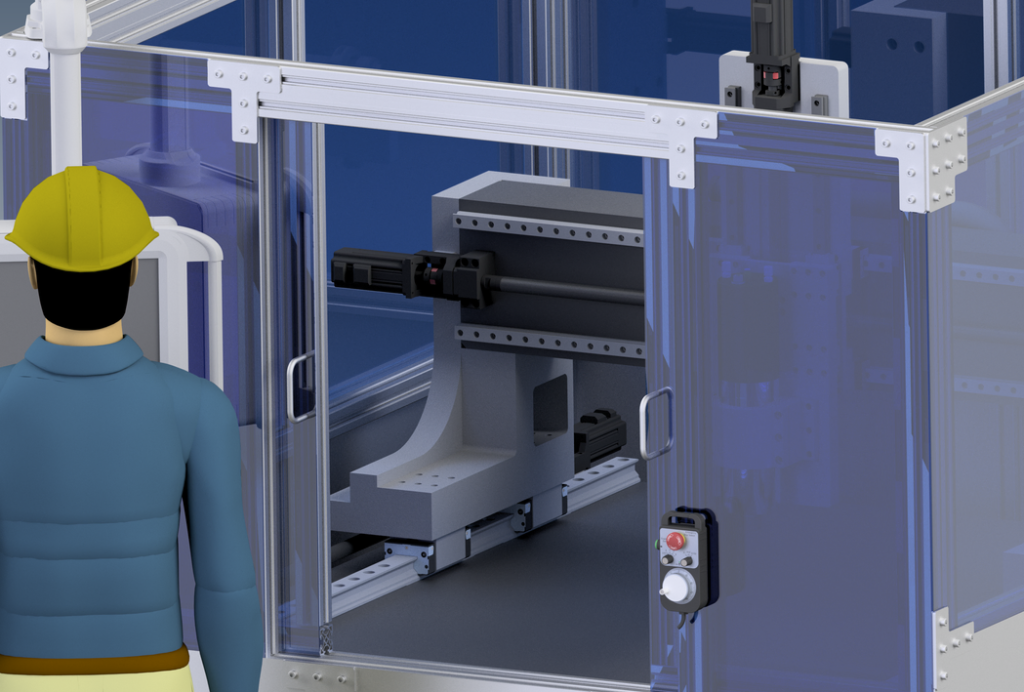

The CNC Router features a gantry arrangement with a highly vibration-resistant granite-composited bridge driving along the X-axis, ensuring smooth and accurate movement of the cutting tool, and a robust 24K RPM spindle with a pneumatic automatic tool changer. The driving components of the machine are sourced from world-known manufacturers such as THK, Siemens, Bosch, and more, guaranteeing the highest levels of quality and reliability.

One of the key features of the CNC Router is the technical 3D model that allows for a detailed and accurate representation of the machine. This model enables the user to visualize and understand the CNC Router’s different components, including servomotors, couplings, liner rails and bearings, and more, ensuring easy maintenance and troubleshooting in the event of any issues.

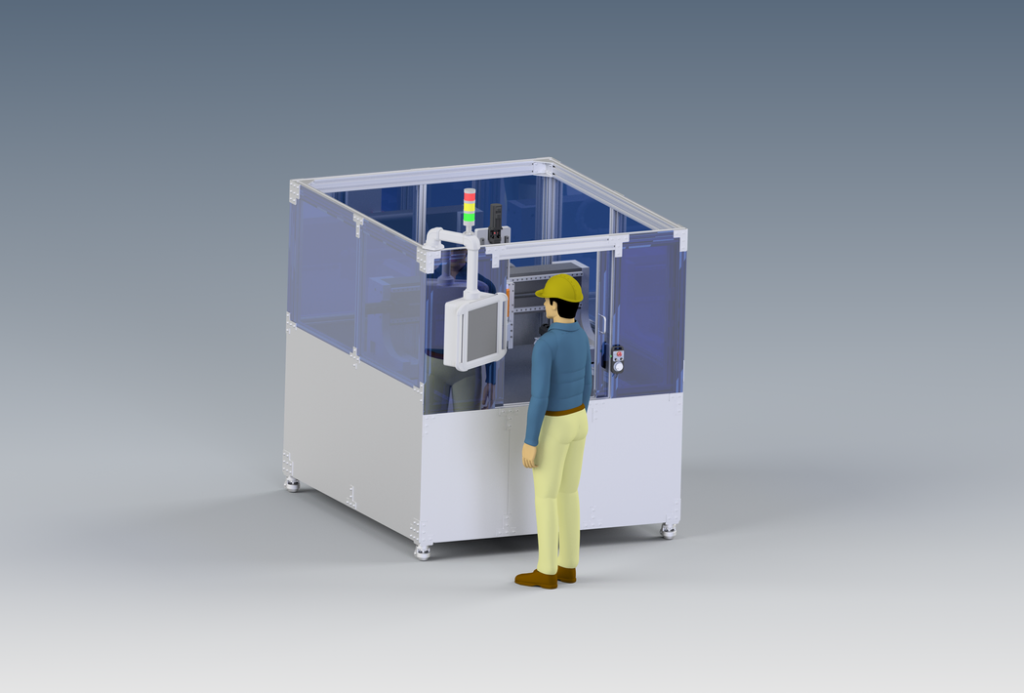

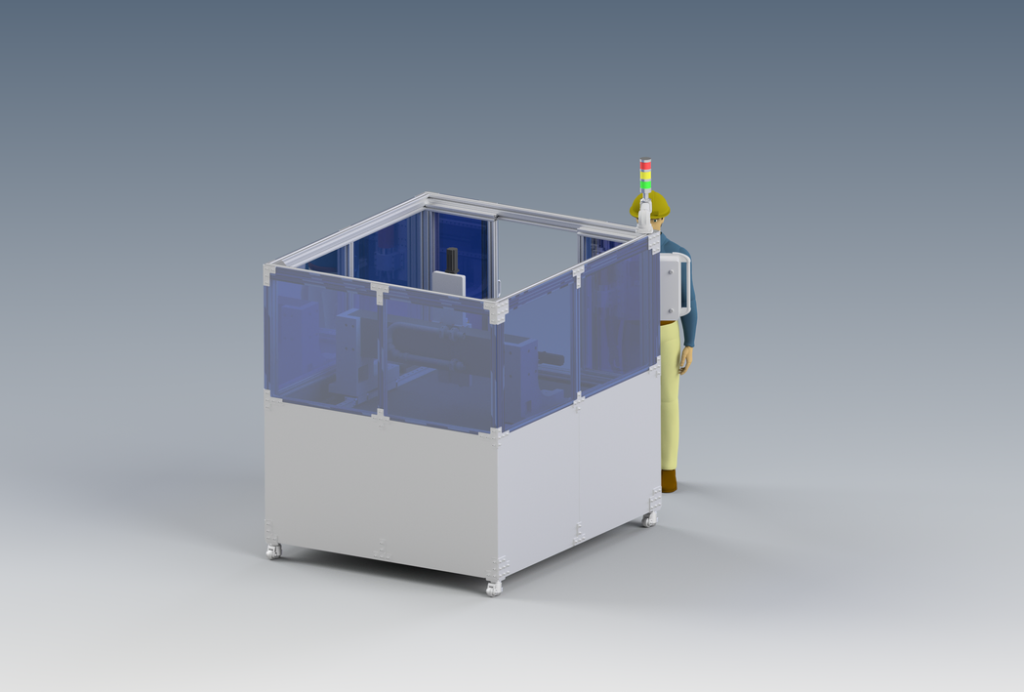

The aluminum frame is another crucial component of the CNC Router, providing strength, durability, and stability to the machine. The aluminum frame is manufactured completely from Item24, a high-quality material that is renowned for its strength and robustness.

The CNC Router has been designed with the highest level of precision in mind, enabling the machine to manufacture high-quality aluminum parts with a high degree of accuracy and repeatability. The machine is versatile and can be used in a wide range of applications, including aerospace, automotive, and other precision manufacturing industries.

The CNC Router has undergone extensive testing and quality checks to ensure it meets the highest standards of performance, reliability, and safety. It is designed to operate with minimal maintenance requirements, making it a cost-effective solution for high-precision aluminum part manufacturing.

Machine Working Area: 1000mm in X, 1000mm in Y and 240mm in Z direction. Highly efficient cooling system integrated with special feature for chips flowing off the back of the machine.

This will close in 20 seconds